Due to its strong corrosion resistance, durability, and ability to be thoroughly cleaned, disinfected, and sterilised safely without degradation, stainless steel products are used across various industries, including medical, automotive, food processing, industrial and mining.

Stainless steel’s endurance, low maintenance costs, longevity, and highly recyclable content ensure a highly cost-effective and environmentally friendly solution.

Sanitary Stainless Steel Seamless Tubing/ Tubos sin soldadura de acero inoxidable sanitario

Sanitary stainless steel pipe is mainly defined according to the surface finish, oil forbidden degree and passivation layer of stainless steel pipe.

Application: Sanitary stainless steel seamless tube is mainly used in food, beverage, alcohol, bioengineering and other production equipment and assembly lines.

Main Standard: ASTM A270

Main Grade: 304, 304L, 316L; 1.4301, 1.4306, 1.4404

Outer Diameter: 4-630mm

Wall Thickness: 0.5-30mm

Length: Random

Surface Treatment: mirror or as customers’ requirement

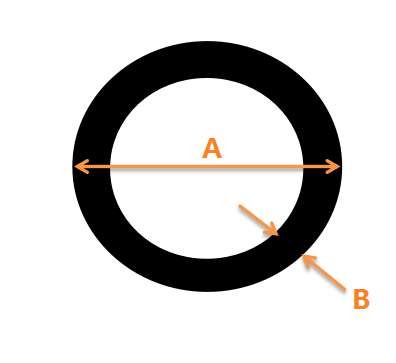

How is it Measured? Outer Diameter (A) X Schedule or Wall Thickness (B) X Length

PS: 304 VS 316L

| 304 benefits | 316L benefits |

| Lower cost | Superior corrosion |

| Easier to weld and form | Stronger and more durable |

| Able to withstand corrosion from most oxidizing acids | Better for marine, offshore and washdown applications |

Advantages Of Seamless Tubes & Pipes

A. Heavy and thick wall thickness

B. No weld seam. Generally be considered as better properties and corrosion resistance

C. Better ovality, or roundness